Here are some approval numbers from the United Kingdom and Australia – UK Coal Approval No. UKC500G and Australia Queensland Mine Dept approval QMD 997449X.

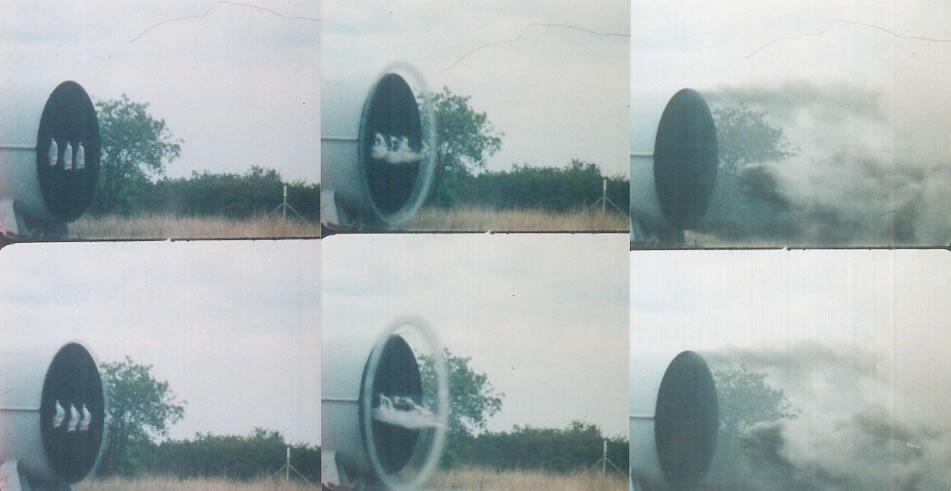

A simple and proven technology, the stonedust barrier is erected as a means to arrest explosions. Containers of stonedust are burst by the pressure wave in front of the explosion and flame. This produces a dense cloud of inert dust which blankets the flame and stops further propagation of the explosion.

Stonedust barriers are low cost safety measures that are easy to implement and have been proven to stop the spread of an explosion.

NIOSH tested this system at the Lake Lynn Experimental mine in 1999 and concluded that the design “was effective in stopping coal dust explosion… within the barrier zone.”

- Proven to be at least as effective as traditional stonedust barriers at lower cost and greater flexibility – requires lower threshold pressure to operate

- Can be used in a number of different configurations including a fixed distributed barrier suggested for use in longwall gateroads – guidelines have been developed for their design, installation and maintenance.

- A bag barrier consists of an array of specially made plastic bags holding 6kg of stonedust

- Plastic bag is designed to shred easily under explosion pressure to disperse dust

- Plastic hook and ring arrangement used to seal and hang bag from the mine roof

- Provides protection against moisture to prevent caking and allowing ease of installation

- Easy visual inspection and repair of barrier

- Great flexibility to handle obstructions such as vent ducting, monorails and conveyor belts for easy installation